Your Trusted Partner for Advanced CNC Spring, Wire Form, & Gear Hob Machinery Solutions

We understand the importance of efficiency and reliability in your operations. Sjoy Machinery offers high-quality machines to help your business succeed.

Sjoy-Since1991, From China

Choose Your Preferred Equipment

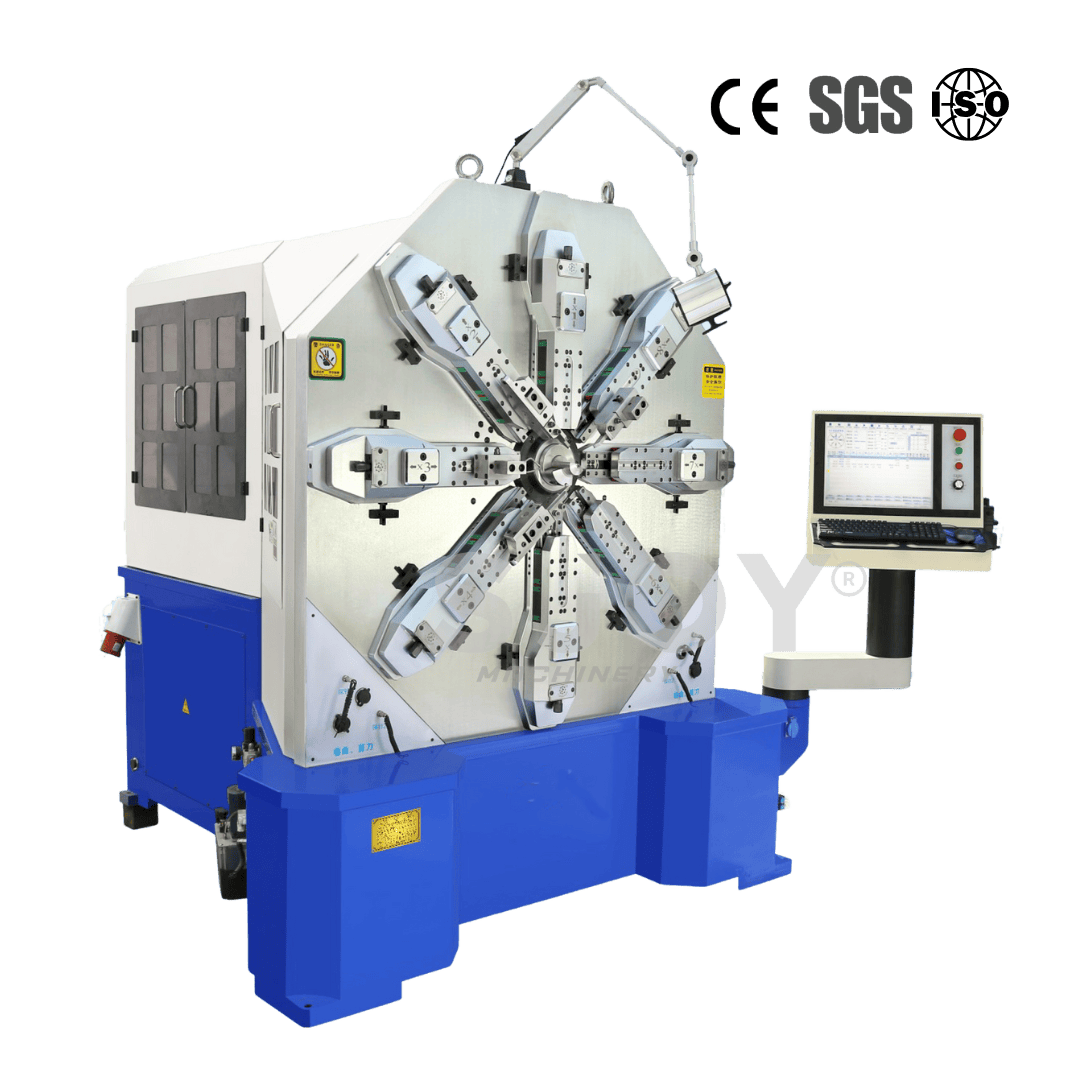

CNC Camless Spring Form Machines

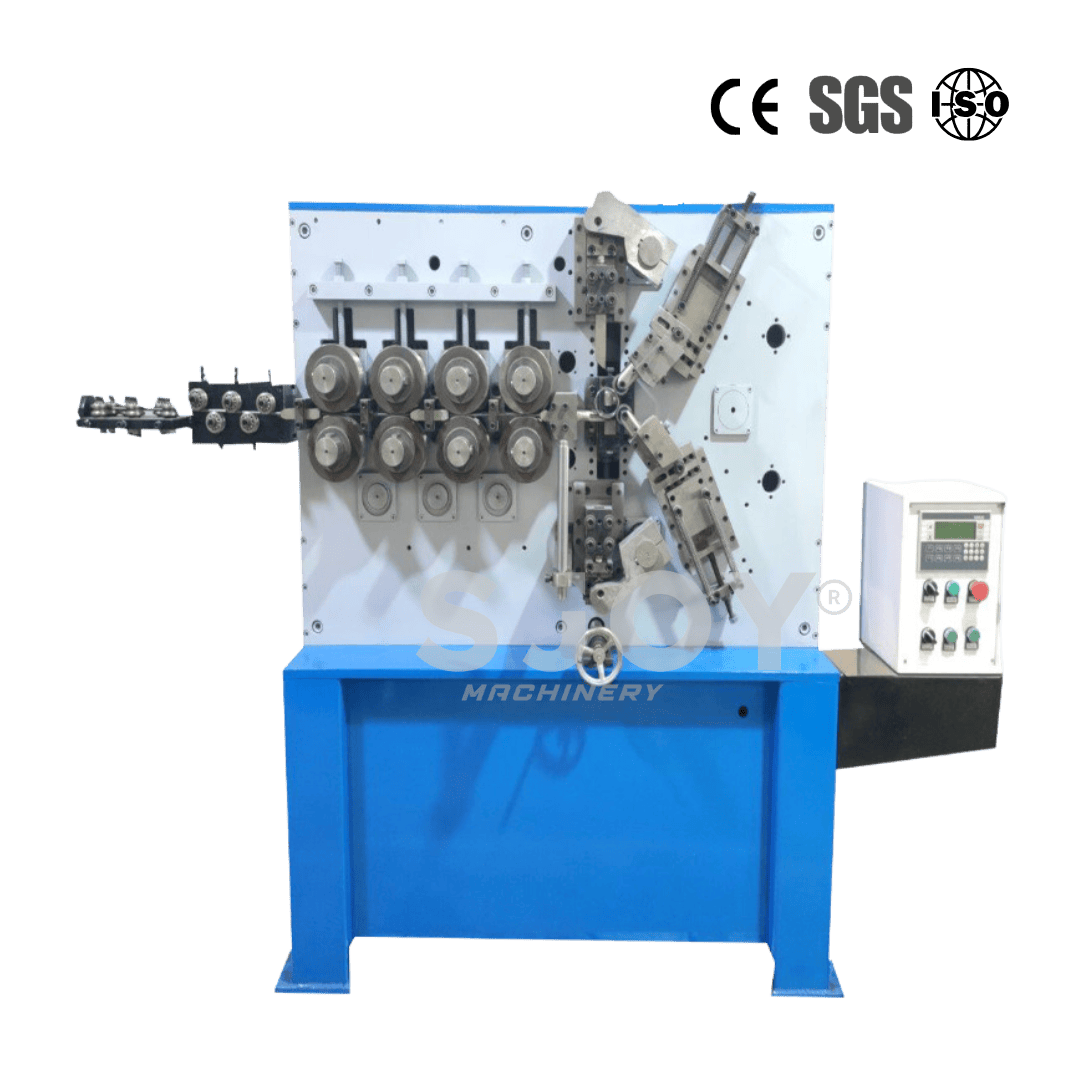

CNC Spring Coil Machines

CNC Spring Form Machines

CNC Horizontal Gear Hob Machines

CNC Horizontal Gear Hob Machines

CNC Vertical Gear Hob Machines

Rolling Door Spring Machines

CNC Spring Grinding Machines

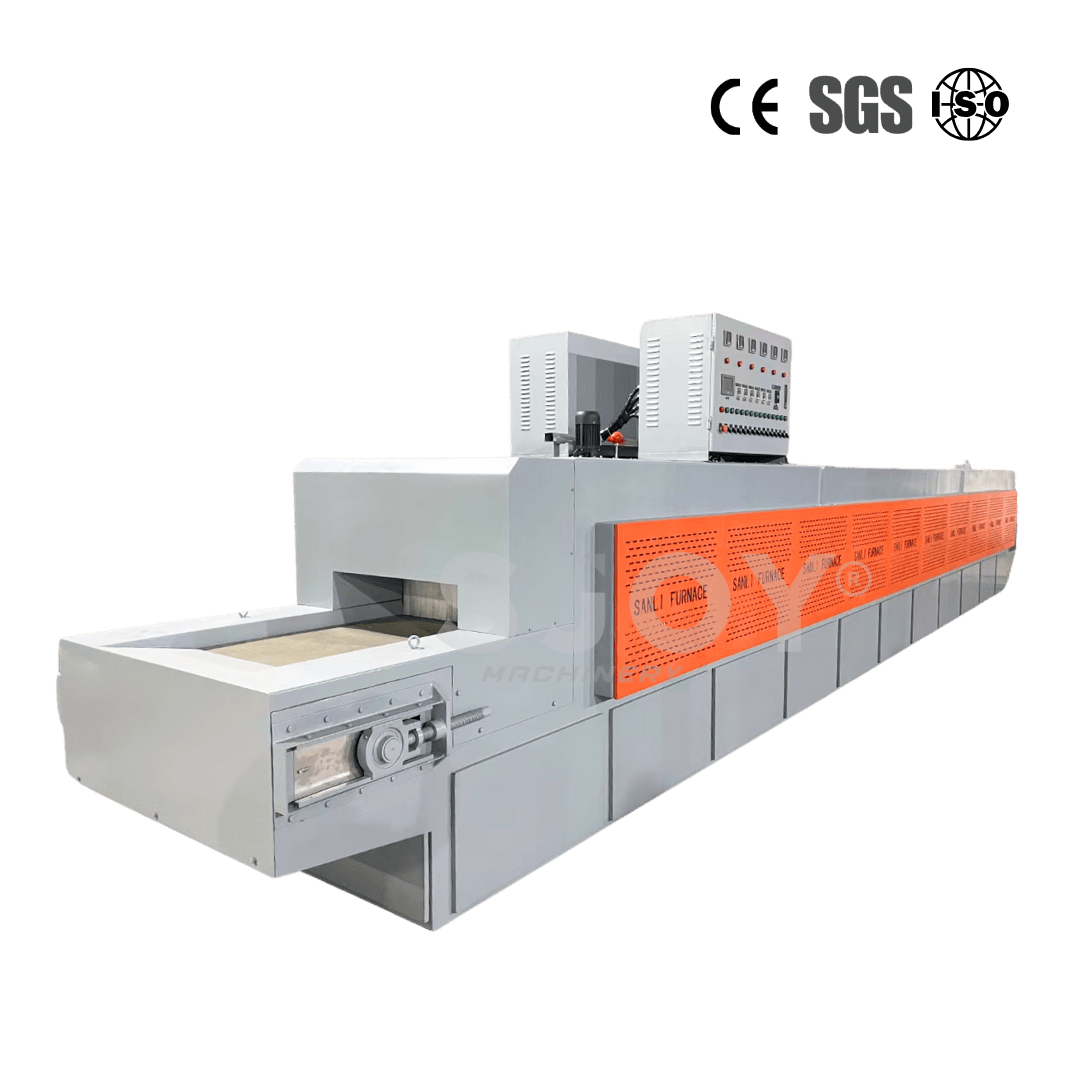

Spring Temper Furnaces

Discover Our CNC Spring & Wire Form Machines

From 2 axes to 16 axes , handling wire diameters from 0.10mm to 23.00mm

Our machines are designed to boost your production efficiency and meet diverse manufacturing needs.

Ready to Enhance Your Production with Sjoy?

Expore more about our CNC Gear Hob Machines

We provide reliable CNC gear hobbing machines to 2000mm+ and 24 module+

Our range includes both vertical and horizontal CNC gear hobbing machines for various applications.

Know More about US

We are here to support you with any information you need.

Free Operation Training

Ensure your team to operate our machines effectively.

Lifetime Supply of Accessories

Ongo spare parts to keep your operations running smoothly.

Fast Delivery Time -7 Days

We strive to deliver your orders the most promptly.

48,000 m2 Huge Workshop

Expansive workshop for production and assembly.

Experience Efficiency and Reliability

We are committed to providing solutions that enhance your productivity.

Over 30+ Years of Manufacturing Experience

With decades of expertise since 1991, we understand your needs.

With CE, ISO, and SGS certification

Our products have certified with CE, ISO, and SGS, ensuring high-quality standards.

Within12 Hours After-Sales Support

We guarantee a response to your service inquiries within 12 hours.

Price

From USD8,500

Warranty

2-Year For Major Parts

Languages Support

Communication In All Languages

Get A Quickly Quote

Yes, our machines are certified with ISO, CE, and SGS, ensuring they meet international quality and safety standards. This guarantees that our equipment is reliable, durable, and compliant with global regulations. If you need specific certification details, feel free to contact us!

The delivery time typically ranges from 7 to 15 days, for our standard machine styles. For customized equipment, delivery may take longer.

Yes, we provide comprehensive technical support and free operator training, ensuring smooth installation and operation of our machines.

es, we offer detailed operation manuals and demonstration videos to help you understand and use our machines effectively.

Yes, dears! We offer customization options to adapt the machines to your specific production needs and technical requirements.

Get Answers to Your Questions

Our team is here to assist you with any questions or concerns. We offer quick responses to help you make informed decisions.

Time Operasional

24-Hour Service

Call Now

+86 577 88808796

Location

Wenzhou, China

Send Us a Message Now

Please click following button to contact us. We will reply you within 15 minutes!